ATS

High-precision centering, alignment and machining of mounted lenses and lens groups

Versatile

High manufacturing accuracy

High profitability

Products

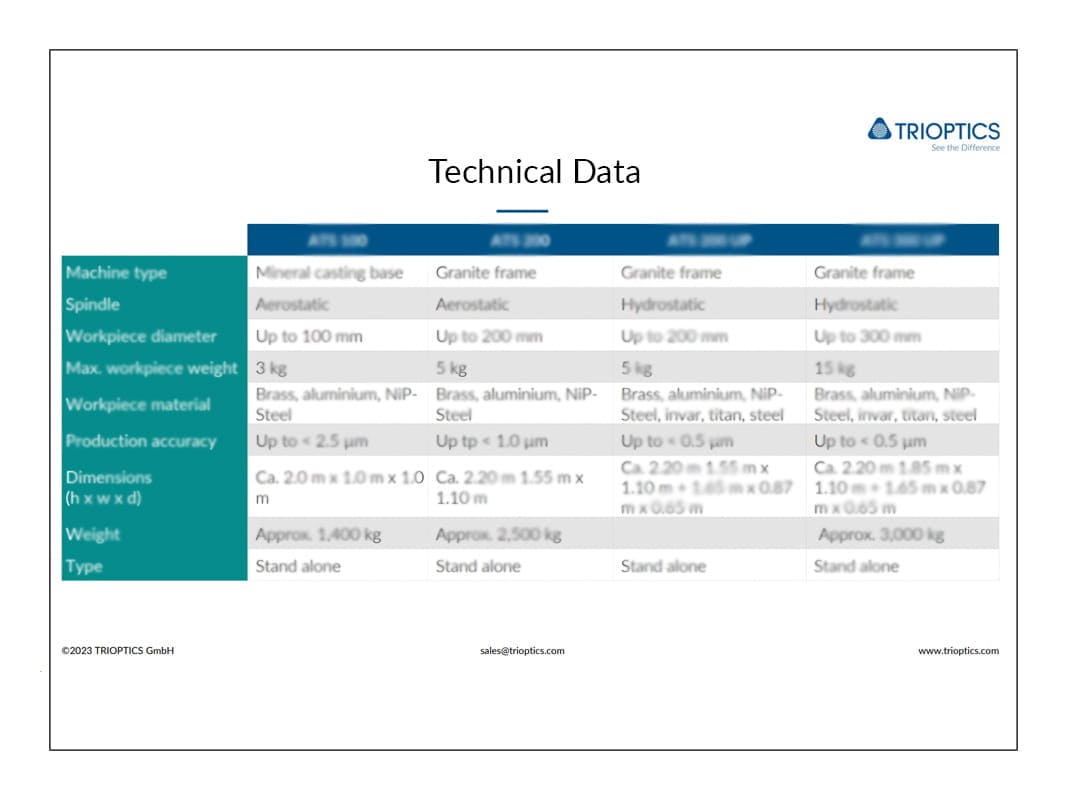

ATS 100

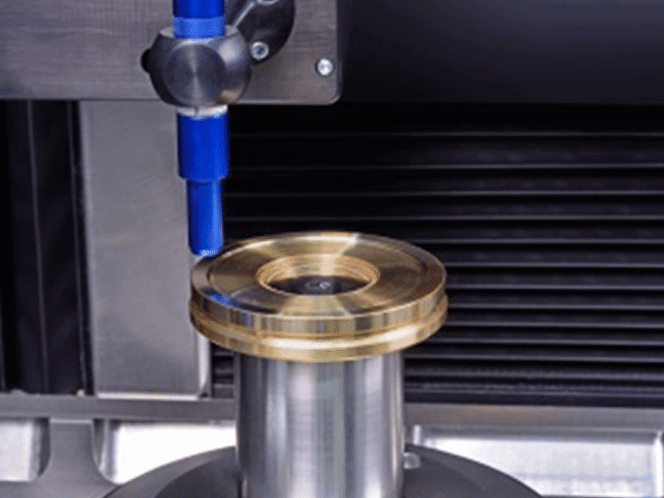

The compact alignment turning station

ATS 100 is optimized for the processing of lens systems with a diameter of up to 100 mm and a weight of up to 3 kg.

- Automated alignment chuck

- Reproducible manufacturing with a repeatability of better than 2.5 µm

- Easy to clean via integrated chip extraction

- Suitable for cycle time optimized processing of large batch sizes

ATS 200

The high-precision alignment turning station

ATS 200 is designed for processing small and medium-sized lenses in medium batch production.

- Optional with hydrostatic spindle

- Automated adjusting chuck

- Great stiffness and thermal stability due to optimized granite base

- Reproducible manufacturing with a repeat accuracy of better than 1.0 µm

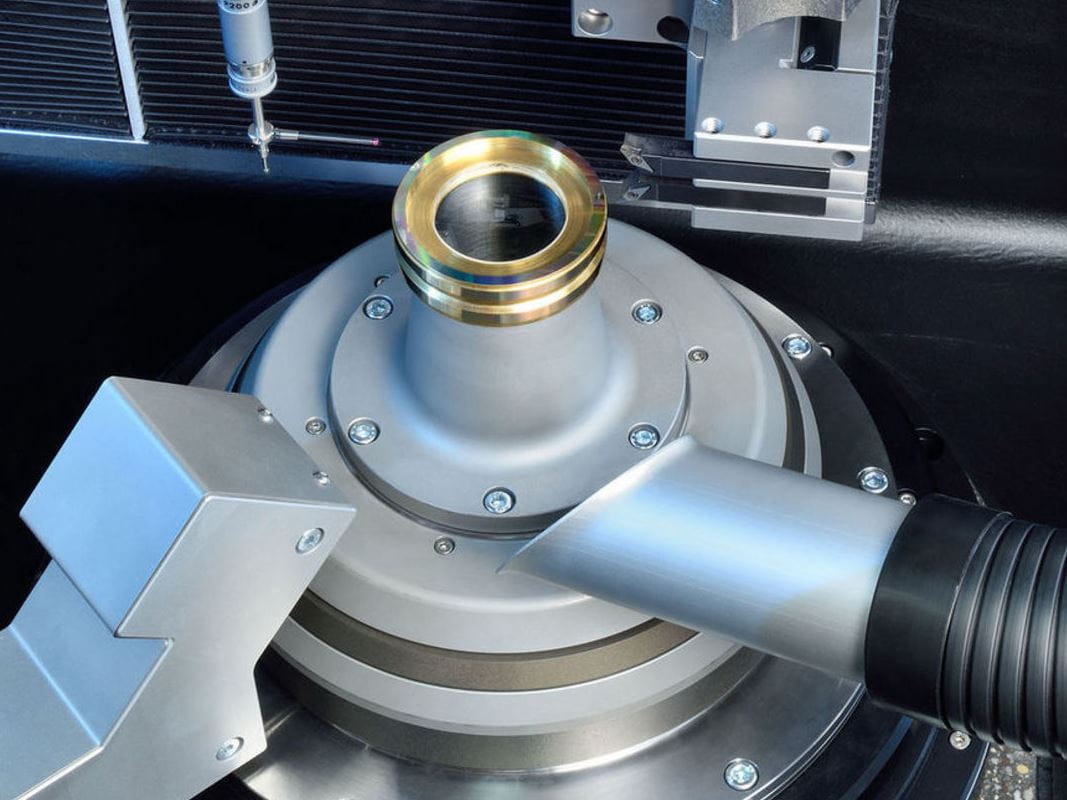

ATS 300 UP

Flexibility in the lens diameter

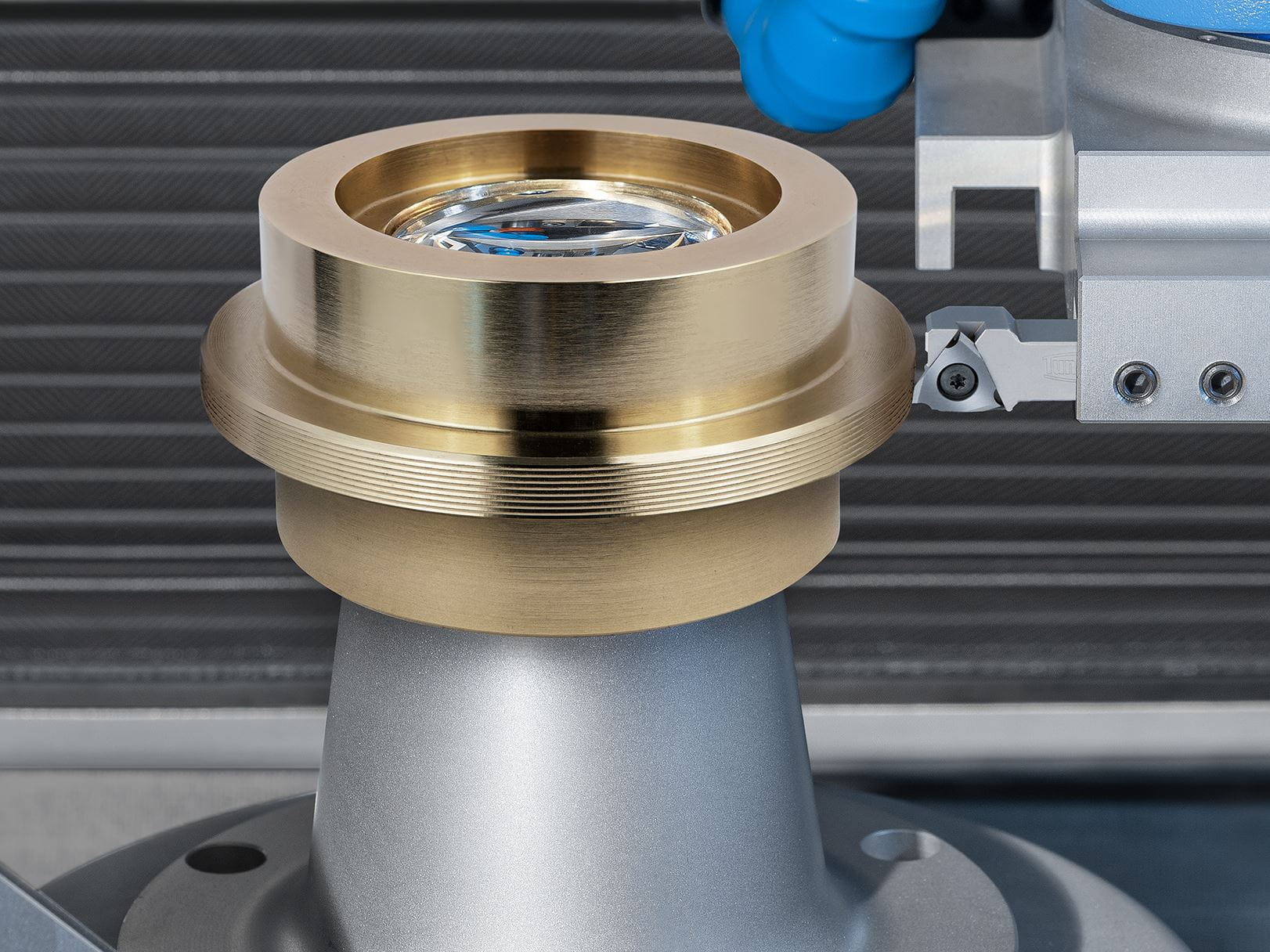

Mounted lenses up to a diameter of 300 mm are machined with high precision by the ATS 300 UP.

- Hydrostatic spindle

- Excellent damping ensuring very high accuracy requirements of up to 0.5 µm

- Comprehensive accessories

Videos

Software

ATS Control

One software for all measurement and production processes

The ATS Control combines operation of the machine functions with the routines for measurement of centering error and alignment. The user is guided step by step, both in setting up sample geometry and carrying out the processing procedure. The software continually monitors the results of the production process.

Newest updates

Our team of experts is continuously enhancing and expanding the capabilities of the ATS Control software. Recent developments include:

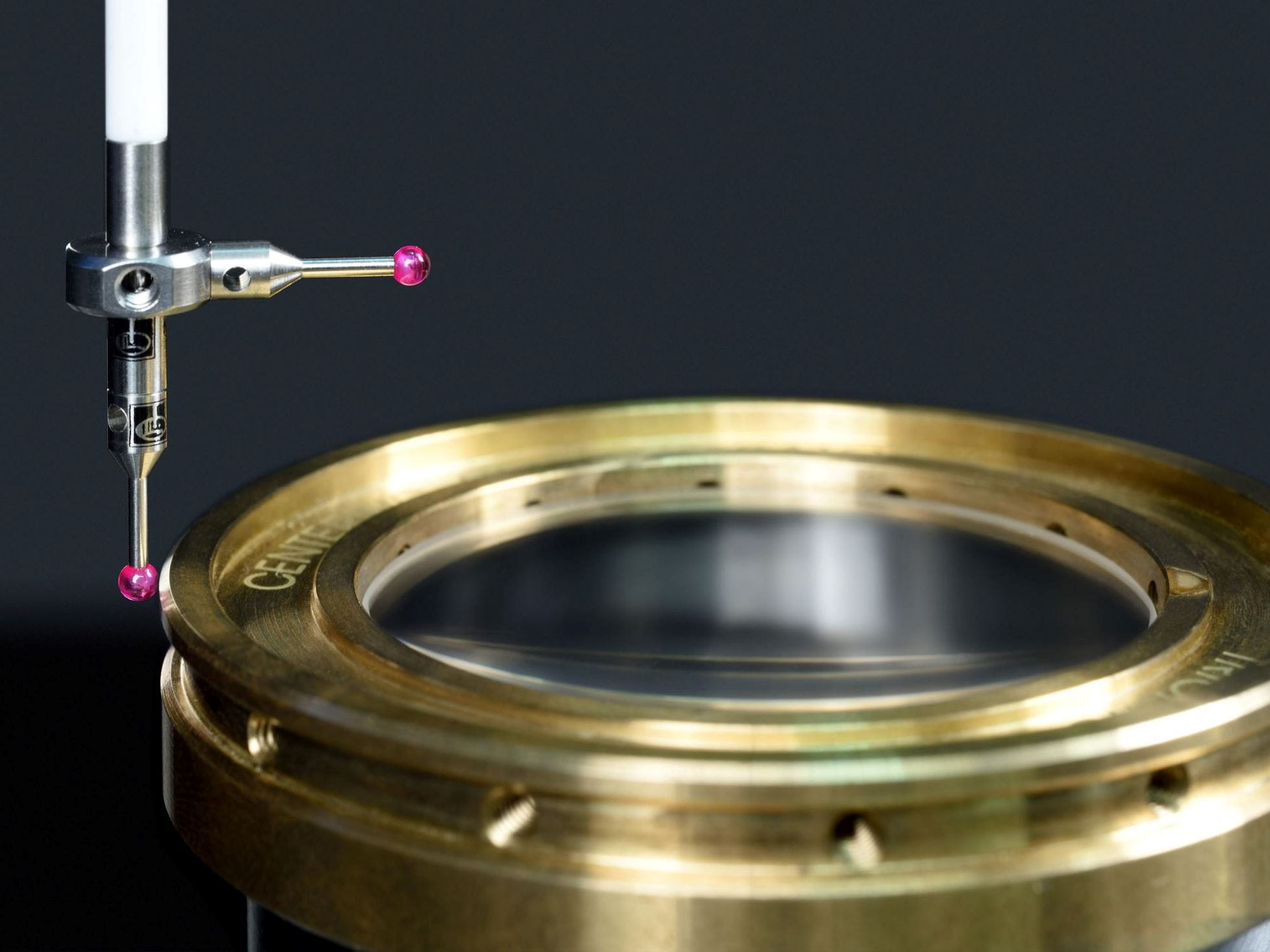

- High-precision probing

Our ATS alignment turning machines have always been equipped with highly accurate mechanical components, enabling us to strike the perfect balance between measurement precision and process speed in standard settings. For applications that demand the utmost precision, we've developed a new software mode that allows for high-precision mechanical probing of the mount and the lens vertex. This, in turn, enables even greater precision in subsequent processing. - Enhanced AspheroCheck® measurement routine

Our asphere measurement routine has undergone a comprehensive overhaul: The new development improves the AspheroCheck® measurement, enabling even more precise alignment and centration of the aspheric axis in the processed, mounted lens. - Measurements of centering errors

The integrated measurement functions have been expanded based on the established technology of OptiCentric®. Likewise, the results can be exported with meaningful measurement protocols, enabling easy further processing.

Upgrades

- Aerostatic spindle

- Hydrostatic spindle

- Tactile sensor

- Optical sensor

- Temperature sensor

- Workpiece temperature sensor

- Sensor for aspheres

- Second autocollimator

- Quadruple tool changer

- Head lens changer

- Minimum lubrication

- Chip extraction

- 2D code reader

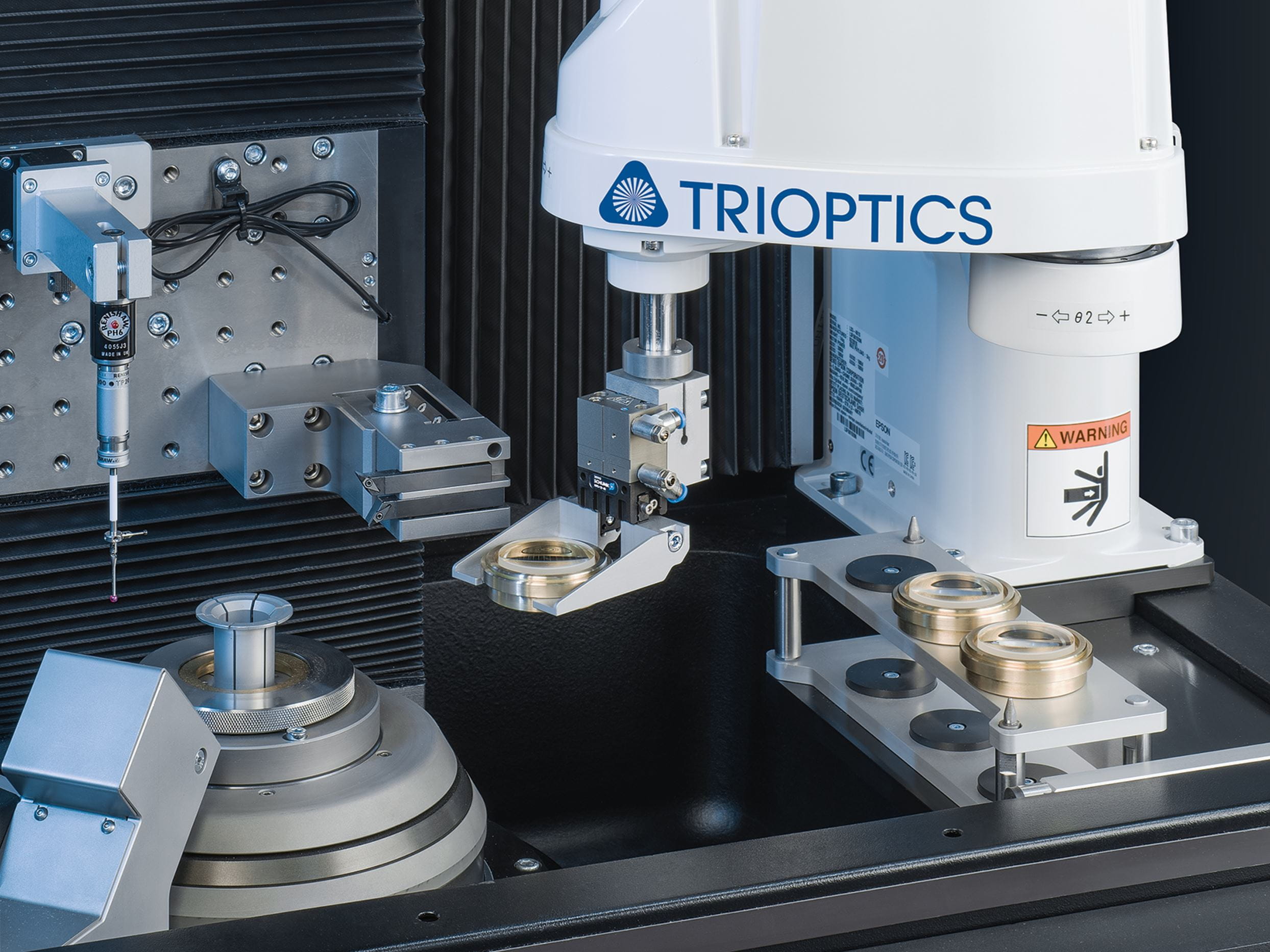

- Increases in efficiency by adding a robot to the ATS for automatic loading and unloading.

- Cutting of threads and grooves

Are you interested in a product and would like to receive a quote?

Whether you need advice or already have specific requirements, we will be happy to help you!

Use our contact form and get quick feedback from our experts.