CamTest

Complete performance testing of camera modules

Versatile

Comprehensive

Intelligent

Products

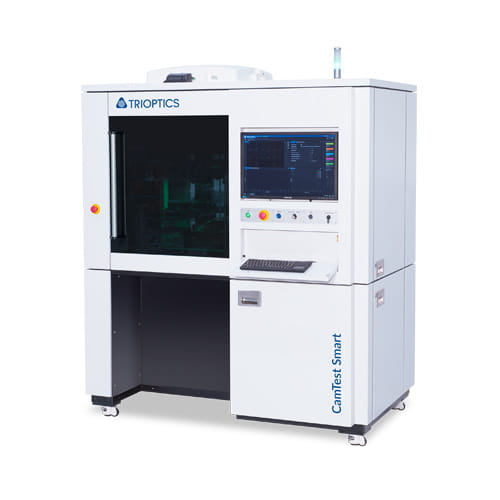

CamTest Smart

The most versatile measuring system

CamTest Smart is an end-of-line test system that enables comprehensive testing of camera modules. With the help of focusing collimators, a test chart and an integrating sphere integrated in only one device, the End-of-Line test can be realized.

- Testing of all essential image quality characteristics of camera modules in just one system

- Flexibility with regard to different camera types

- Flexible low to mid volume production and R&D

- Fully automated process

- MTF, LSF, SFR, ESF

- Image plane tilt, Defocus, DOF

- Boresight shift, Roll angle

- Optical centre

- Distortion, EFL

- Defect pixel, Particle, FPN

- OECF, Dynamic range, White balance, SNR

- Relative illumination

- Color rendering, Crosstalk

- Spectral response

CamTest TempControl

Camera module temperature tests

CamTest TempControl determines the image quality of optical sensor systems under the influence of temperature. The instrument simulates the real temperature conditions in a climatic chamber.

- Highly accurate measurement in a temperature range between -40°C and +120°C

- Individually configurable and automated measurement routines

- Comprehensive analyses of camera behaviour to identify product optimisations.

- Measurement data (e.g., focus position or image plane tilt) at different temperatures and their effects on the image quality are stored in a database.

- High flexibility: Different sensor formats (such as 1:1, 4:3, 16:9 and many more), different spectra (VIS, NIR, LWIR) and changeable measurement positions.

CamTest Focus

Determination of best focus plane

The collimator virtually projects the target onto the sample. By using focusable collimators, any object distance of 1m to infinity can be generated. This makes it possible to measure the position and tilt of the best focus plane.

- The setup provides a field of view of +/-90°

- Variable object distance from finite to infinite in just one measurement setup

- Measurement of various parameters such as: MTF, SFR, through-focus MTF, image plane tilt, boresight shift, roll angle

CamTest Focus OEM

One-stop solution for focus measurement

A simple, easy-to-use and easy-to-integrate camera testing unit that includes the optomechanical setup with our industry-leading motorized collimators and focus measurement software to check the camera's image quality in just 2 seconds.

- Shortest cycle times thanks to high scanning speed

- Industry-leading motorized collimators achieve outstanding accuracy

- ProCam® Focus measurement software with high-precision image quality evaluation algorithms for real-time analysis

- Easy integration into existing customer production lines and uncomplicated handling

- High flexibility for easy adjustment of collimators to camera systems and FOVs

- Standard TCP/IP interface for faster data acquisition and control

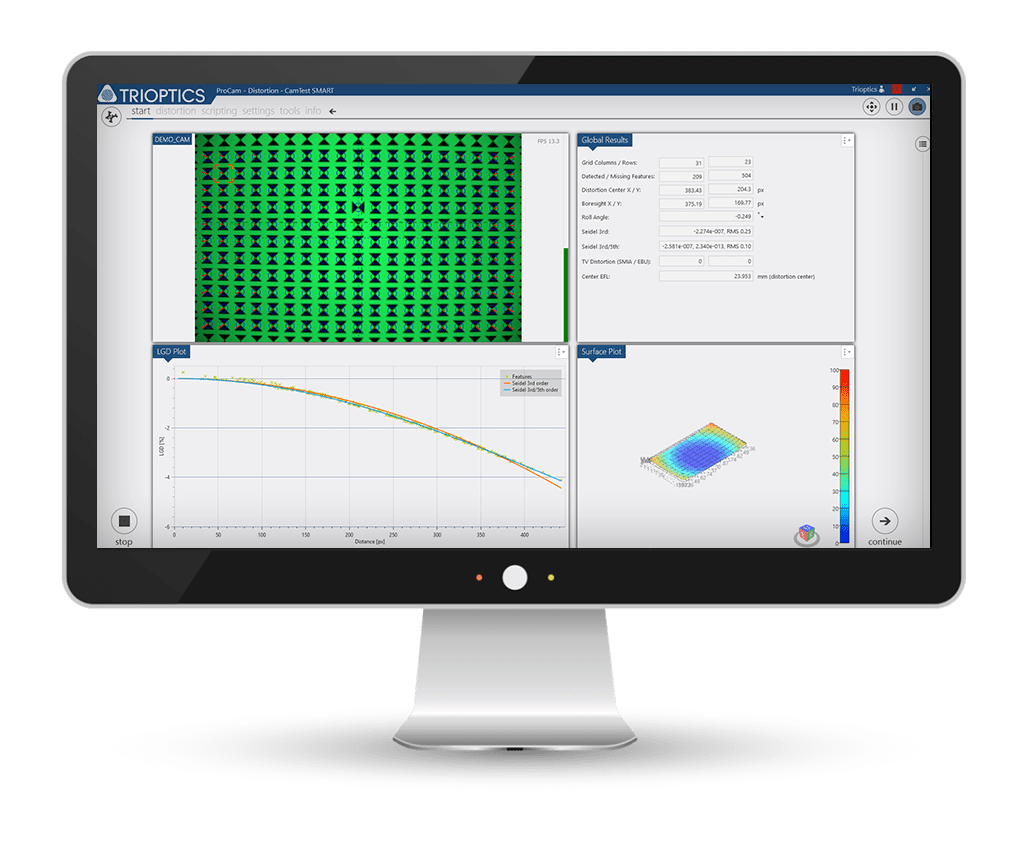

CamTest Chart

Easy measurement of distortion

The CamTest Chart system projects a test target from finite or infinit object distance to the camera module under test. For an infinite test setup a specially designed relay optic is used. With the help of a suitable optical structure, cameras with a highly distorted optical system can also be calibrated.

- Measurement of: camera lens geometric distortion (LGD), TV distortion, camera boresight and optical center, camera EFL and FOV

- From the distortion measurement the distortion coeffecients (Seidel coefficients) are obtained used for the calibration of the camera module under test

- Especially relevant for ADAS (Advanced Driver Assistance Systems)

- The relay optic is available as an upgrade

CamTest Spectral

Determination of sensor parameters

The CamTest Spectral comes with an integrating sphere in finite object distance. The integrating sphere serves as a light source in order to obtain the diffuse light required for the measurements.

- Measurements of camera modules with up to 160° field of view

- The sphere allows a light uniformity of more than 95 %

- The setup is particularly well-suited for measuring parameters such as defect pixels, FPN, color rendering, OECF, relative illumination and dynamic range

CamTest MTF

One-shot MTF measurement

In order to test camera modules with larger object distances, a structure with fixed collimators, which are preset for infinite or finite object distances, is suitable. In this case, the field of view depends on the actual object distance.

- With this set-up, the MTF can be quickly and easily determined

- Furthermore, also Line Spread Function, SFR and ESF can be measured

- This method is escpecially suitable for a final quality check in high volume camera production

CamTest R&D

High-precision image quality test

The CamTest R&D is a high-precision measurement device for testing a variety of image quality parameters of camera modules. The computercontrolled test target distance can be freely selected from finite distances to infinity using a focusing collimator.

- Available for various wavelength ranges (VIS, NIR and LWIR)

- Can be used for many types of camera modules

- Ideal solution for comprehensive measurement tasks in the R&D environment

- Wide off-axis angle range of up to +/- 110°

Video

CamTest Smart

100% testing of camera modules in just one compact system

TRIOPTICS offers a 100% testing technology for all essential image quality characteristics of camera modules in just one compact system. It integrates all test parameters in one device. Therefore, along with common optical and opto-mechanical parameters such as MTF, SFR, defocus, image plane tilt and rotation, and distortion, the system also covers additional sensor testing parameters, including OECF, dynamic range, white balance, relative illumination, spectral response and more. Further benefits of the CamTest Smart instrument include: small footprint, flexibility with regard to different products, suitable for flexible low to mid volume production and R&D, and fast changeover times.

Software

CamTest Software

The software is particularly user-friendly. The user is automatically guided through the measurement process. The output of the values can be done as pass/fail output. Measurement certificates are generated directly from the software in order to ensure complete traceability. The CamTest software supports the following measurement parameters and their analysis:

- Image quality features (MTF)

- Optomechanical properties: sensor position (tilt, rotation, defocusing)

- Other optical parameters: distortion, relative illumination, focal length

- Color characteristics: chromatic aberrations

- Lens light reflection

Upgrades

CamTest ColMot 2.0

Optical target projectors for the performance test of electronic camera modules

The CamTest ColMot system is a series of industry-leading optical target projectors providing virtual test targets for the performance test of electronic camera modules or objective lenses. The main application is the test for camera image quality, lens alignment and focus precision.

- KCompact design for dense field of view (FOV) coverage

- Infinite conjugate testing for very wide FOV cameras

- For measurement of MTF/ SFR, through-focus MTF/ SFR, image plane tilt, camera boresight, focus setting and roll angle

- High speed and high positioning repeatability

The CamTest ColMot series is characterised by special robustness and reliability in industrial grade. Another important feature is the closed-loop control for target position and luminance level. A large variety of LED illumination sources, target patterns as well as a software development kit (SDK) and drivers are available. Accurate factory calibration is another advantage of the CamTest ColMot series.

The portfolio includes the following effective focal lengths (EFL): 16 mm, 25 mm, 35 mm, 50 mm, 75 mm, 100 mm and 150 mm.

CamTest ColMot 6.0

Optical target projectors for high-speed camera testing

The CamTest ColMot 6.0 is characterized by a very long product lifetime, high speed for fast measurement and short cycle times. It is very user-friendly and has improved maintainability with an integrated cycle counter, temperature sensor and internal data storage of collimator-specific data.

- Extended product lifetime

- The most compact design for dense field of view (FOV) coverage

- Highest speed for fast measurements and short cycle times

- High positioning repeatability and accuracy

The CamTest ColMot series is characterised by special robustness and reliability in industrial grade. Another important feature is the closed-loop control for target position and luminance level. A large variety of LED illumination sources, target patterns as well as a software development kit (SDK) and drivers are available. Accurate factory calibration is another advantage of the CamTest ColMot series.

The portfolio includes the following effective focal lengths (EFL): 16 mm, 25 mm, 35 mm, 50 mm, 75 mm, 100 mm and 150 mm.

CamTest ColMot 6.0 is particularly suitable for equipping fully automated production and test facilities at the highest productivity level.

CamTest LWIR

Long-wave length infrared collimators for the production of thermal imaging cameras

The first edition of CamTest LWIR collimators enables automated mass production of thermal imaging cameras. For manufacturers of thermal imaging, thermographic or infrared cameras used in the military and in the surveillance of buildings, industrial plants or people.

- Making the invisible visible with the LWIR collimators in infrared technology

- Wavelength range: 7 -12 μm

- Effective focal length (EFL): 50 mm, 200 mm or 500 mm

- 5-axis Controller manages and monitors the lighting, the shutter and the fan

Are you interested in a product and would like to receive a quote?

Whether you need advice or already have specific requirements, we will be happy to help you!

Use our contact form and get quick feedback from our experts.