ImageMaster® AR/VR

Measurement systems for Augmented and Virtual Reality optics

Unique

Extensive measuring parameters

Reliability

Products

ImageMaster® Lab VR

Measurement device for testing VR lenses and lens systems

The ImageMaster® Lab VR was specifically developed for the measurement and qualification of virtual reality lenses.

- Measurement for various pupil distances and sizes

- On- and off-axis measurements allow testing of the entire field of view of the human eye

- Eyebox Scanning

More information

- High contrast programmable display is used as a light source and object generator

- Software-controlled RGB light source for measuring different wavelengths

- Integration of customer display possible

ImageMaster® PRO VR

Measurement solution for testing VR lenses and VR modules in production

The ImageMaster® PRO VR was specifically developed for the measurement of VR lenses and VR module qualification in production environment.

- 1.5 s measurement time per sample

- Measurement possible for various pupil distances and sizes

- On- and off-axis measurements allow testing of the entire field of view of the human eye

More information

- Up to 27 cameras

- Aperture to simulate the specific near to eye display requirements

- Accurate MTF measurement at high spatial frequencies on and off axis

- Software-controlled RGB light source for measuring different wavelengths

- Maximum Field of View 170° (optional)

- Clean room compatible

ImageMaster® Lab AR Flex

The multi-dimensional test solution for AR optics

The ImageMaster® Lab AR Flex is a measurement solution for transmission and reflection waveguides, correction glasses, light engines and complete Near-Eye Displays.

- Testing of AR components, modules and complete headsets

- Accurate MTF measurement at high spatial frequencies on- and off-axis

- Diffraction limited up to 60 lp/° (ISO, traceability, optical standards)

More information

- Eyebox scan at various incident angles

- Adjustable pupil size and eye-relief distance along with the full flexibility of input pupil location in X/Y plane for the complete eyebox scan

- Illumination sources with wide range of wavelengths and polarization

- Motorized optical system for virtual image distance (VID) and diopter measurement

- Metadata like part number, operator, etc. (freely configurable)

- Independent movement of telescope detector and target generator for both on-axis and off-axis measurements, one-shot wide field of view on-axis measurement (on request)

- Fully computerized control measurement sequence with robotic sample handling (on request)

- Precise measurement of image quality parameters such as MTF, sharpness, homogeneity, contrast, distortion, efficiency, color and luminance (on request)

ImageMaster® PRO AR

Fast optical performance testing of waveguides in production

With the ImageMaster® PRO AR, TRIOPTICS offers an accurate and fast production test system for Augmented Reality optics. The ImageMaster® PRO AR measures single components like waveguides and projectors as well as complete AR modules.

- AR measurement solution for manufacturers, integrators, and independent testing laboratories

- Parallel measurement with up to 27 collimators and telescopes

- 0.3 s per measurement point

- Automatic positioning of samples using automated tray system

- Alignment and correlation of measurement data across production lines and R&D instruments

More information

- Measurement at various eye relief distances and with various pupil sizes

- Scanning of exit pupil (eyebox scan)

- Movable telescopes in x and y direction

- Effective aperture scan within exit pupil: Customizable field of view

- Software controlled RGB light source for measurement of different wavelengths

- Waveguide in transmission

- Waveguide in reflection

- Customized tray for sample handling

- Customized base with kinematic mount for quick and repeated loading/unloading of the tray

- AR modules testing (on request)

- AR projector testing (on request)

ImageMaster® PRO AR

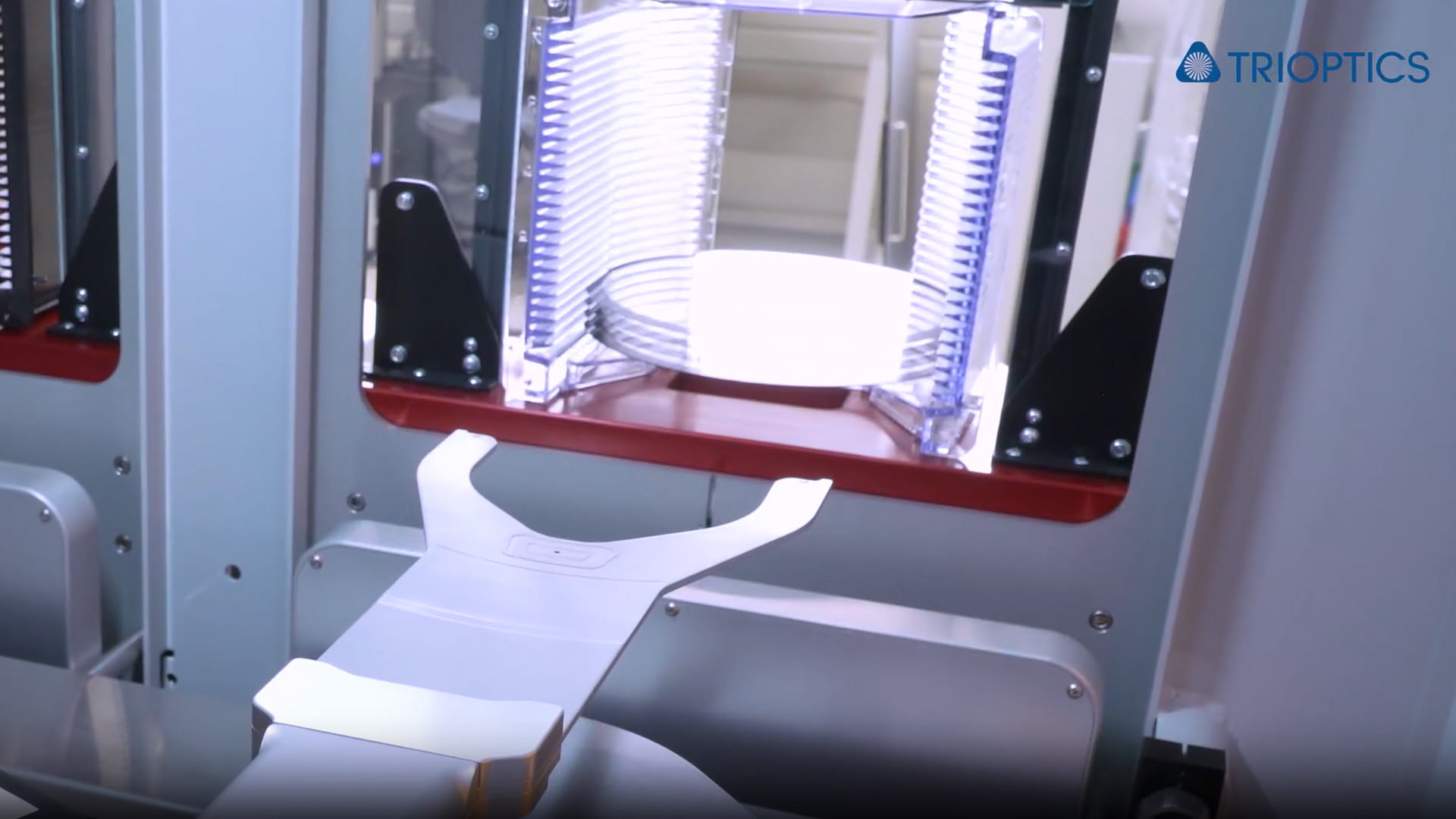

Automated loading and unloading with wafer-handler

The ImageMaster® PRO AR with wafer-handler option enables fully automatic workflows in optical performance testing of waveguides in production. Robotic handling of wafers, a software controlled automatic measurement process and support for various wafer carriers ensure maximum performance and compatibility. The main measurement parameters are contrast (MTF), distortion, efficiency, and chromatic aberrations.

- Highly accurate measurement of contrast (MTF), distortion and efficiency over the field of view and eyebox

- Full eyebox scan, multiple field points are measured in parallel for shortest measurement duration

- Designed for transmission waveguides, optional support for reflection waveguides

- User-selectable pupil size, illumination wavelengths and polarization, as well as eye relief distance

Video

ImageMaster® PRO AR with wafer-handler

Get a first impression of high-speed optical performance testing of waveguides in production. The waferhandler is used for automated loading and unloading in a software controlled and automatic measurement process. In combination with the ImageMaster® PRO AR highly accurate measurement of contrast (MTF), distortion and efficiency over the field of view and eyebox is achieved.Software

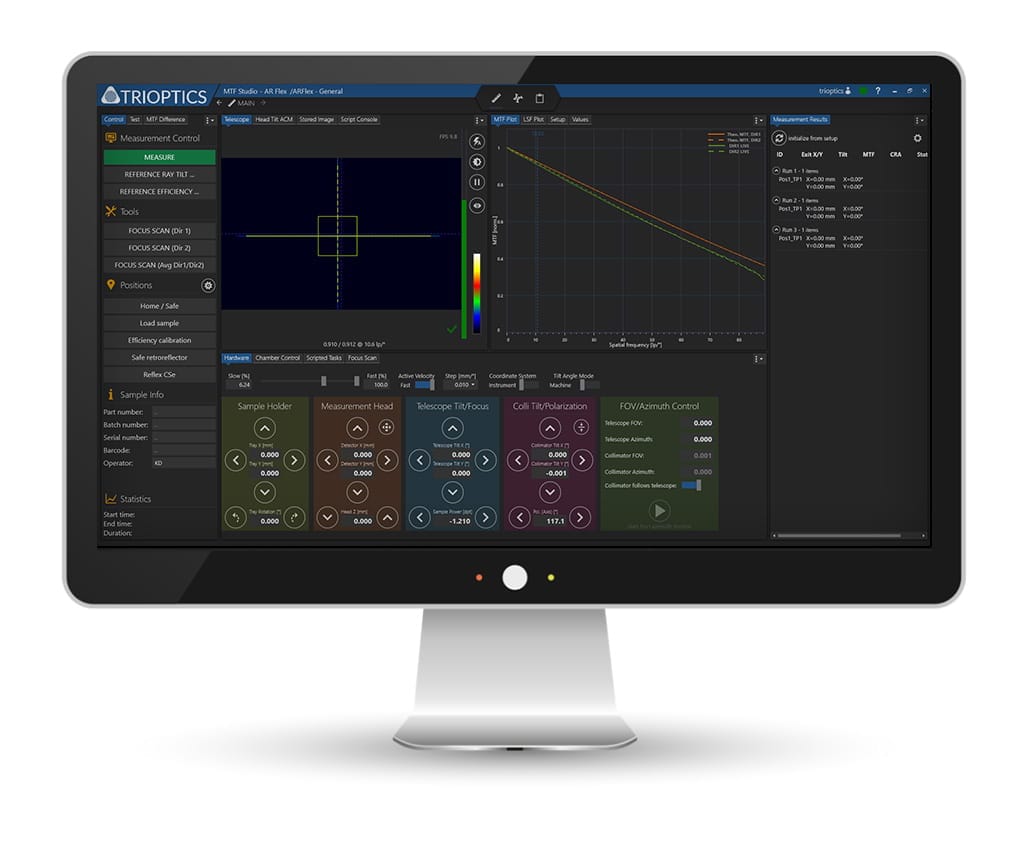

Software for ImageMaster® Lab VR and Lab AR

- Scripting tools for customer-specific programming and analysis

- Functions for easy alignment of the sample

- Intuitive user interface and time-saving lens testing routines

- Certificate output in HTML format, can be imported to MS Excel