Active alignment & assembly of camera modules

Larger sensors, smaller pixels and higher pixel densities are the dominant trends in the high-quality camera module market, presenting new challenges to you as a camera manufacturer? Even with a perfect lens system, the image quality of a complete camera will deteriorate if the lens is poorly aligned with the sensor. This effect is amplified with increasing camera power and the sensor’s higher resolution. Manual mounting of high-quality components results in a poor image due to standard mechanical mounts such as C-mount or F-mount. The tolerances used in the production of standard versions are far too small for high-resolution camera applications. For this reason, precise active alignment of the optics and sensor is essential in the production of modern camera systems. The alignment process ensures that the full-scale performance of the lens and sensor is utilised. The most important production step is the alignment of the optics relative to the camera sensor.

Automotive

- ADAS (Visible camera, 3D camera, Night vision camera, LiDAR)

- Interior observation, DMS, Head up Displays, Touchless Control

- Mirror replacement

Industrial applications

- Machine vision

- Barcode readers

- Navigation & Geospatial

- Smart farming equipment

- Borescopes

Security, Healthcare & Consumer electronics

- Surveillance

- Medical cameras

- Endoscopes

- Video conferencing

- Sport & entertainment

Coffee Break

No time for long explanation videos?

Get the essentials on a wide range of technology topics during a coffee break.

ADAS Camera Production Line

Advanced driver assistance systems (ADAS) and autonomous driving (AD) technologies in cars require highly reliable image processing systems and optical sensors for road safety. This places high demands on the 24/7 mass production of automotive cameras. Watch the video to see how we fulfil these requirements with ProCam® TT!

Success Story

Strong trust in our expertise

A success story with Allied Vision

A new optical standard for industrial image processing

We support manufacturers and suppliers in ensuring the quality, reliability and durability of their optical sensor systems. Our solutions for active optical alignment and assembly enable the series production of optoelectronic systems. Read the success stories of our customers and find out how active alignment becomes a game changer.

Knowledge base

The potential of active alignment

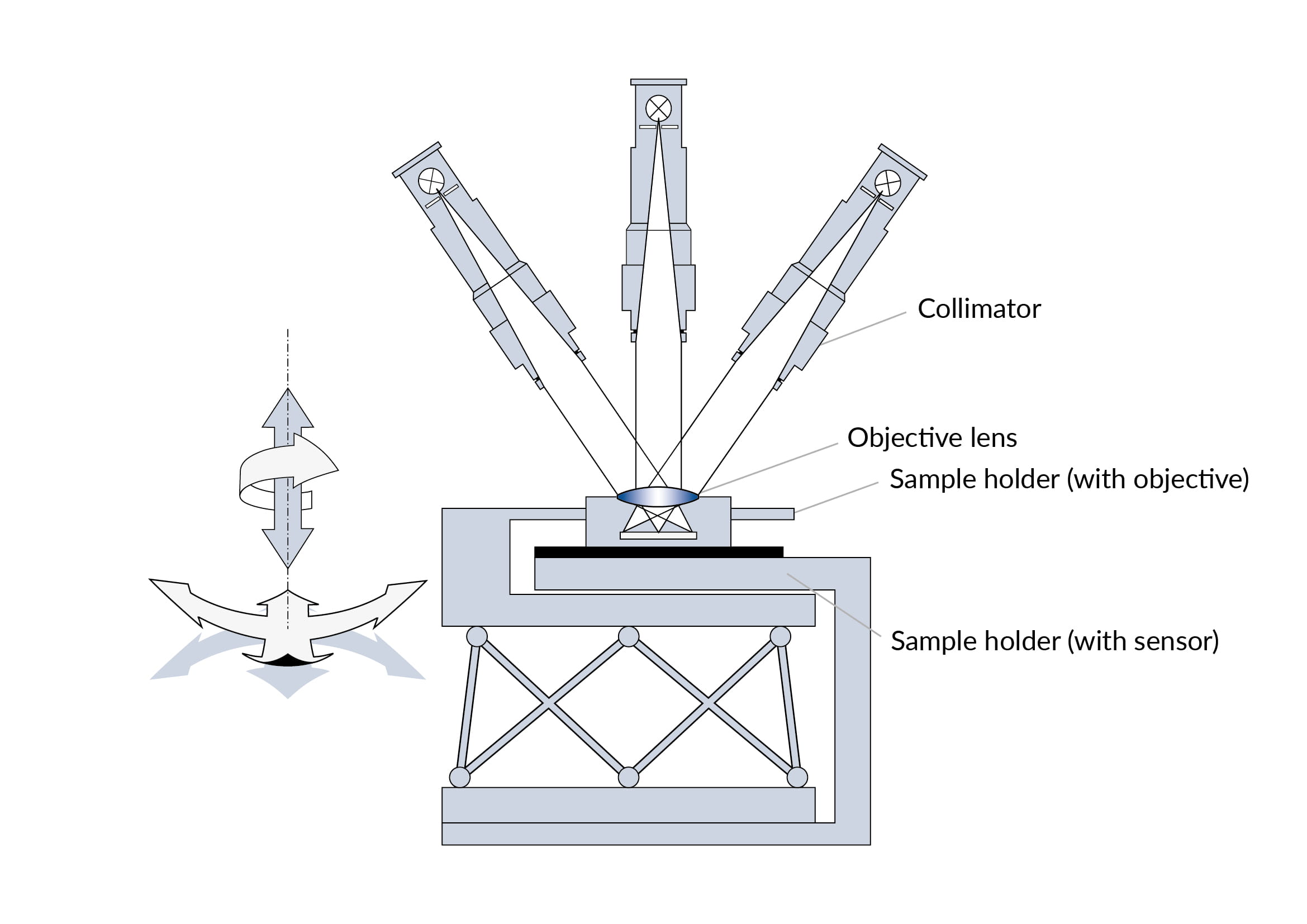

The image acquisition and transfer time for most camera modules is short, so the data obtained from the Device Under Test (DUT) also can be used in production to align the optics and sensor proactively and automatically to each other in a real-time, closed-loop process so that the combination delivers the highest possible performance. Besides the simple three-axis alignment for focusing (Z) and centering (X-Y) of the sensor, rotation and, especially, sensor tilt relative to the image plane of the optics can be adjusted. The tilt adjustment becomes increasingly important for high-performance, high-resolution modules with short depth of focus to reach the required image quality. As sensor resolution increases and the required tolerances become smaller, the industry is forced to use automatic alignment systems instead of further reducing manufacturing tolerances.

Depending on the application, either a collimator arrangement or a finite test chart is used to provide the required information for the multiaxis active alignment system. To fix the achieved camera alignment, a glue dispenser with UV light curing can be embedded into the system, making the instrument a fully automated fabrication station for camera modules.

Our Newsletter – Your advantage in knowledge

Be one of the first to experience our product novelties and innovative application possibilities.