Alignment and testing of optical systems for infrared radiation

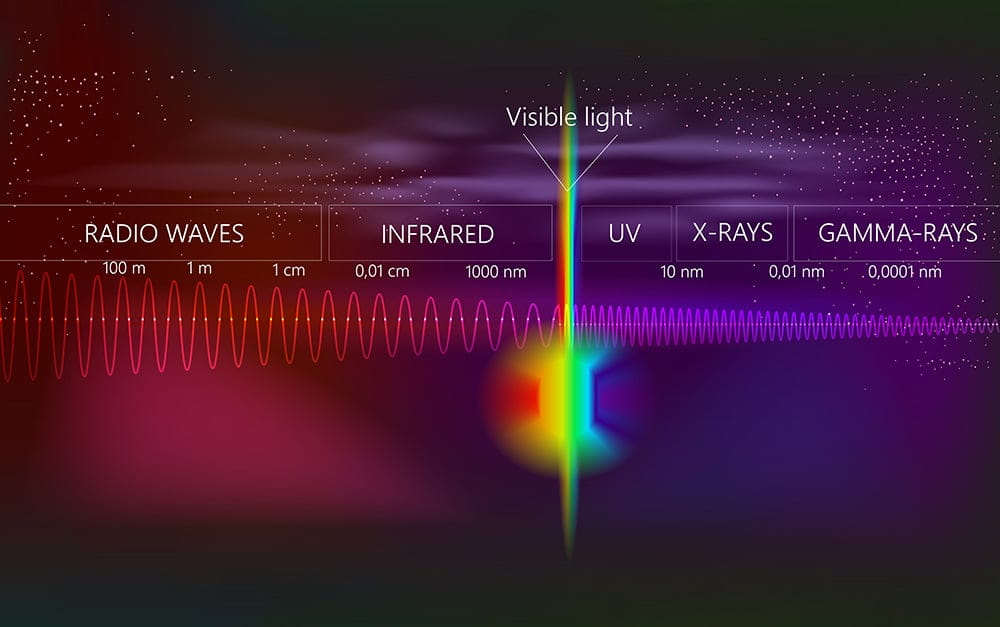

Beyond the visible

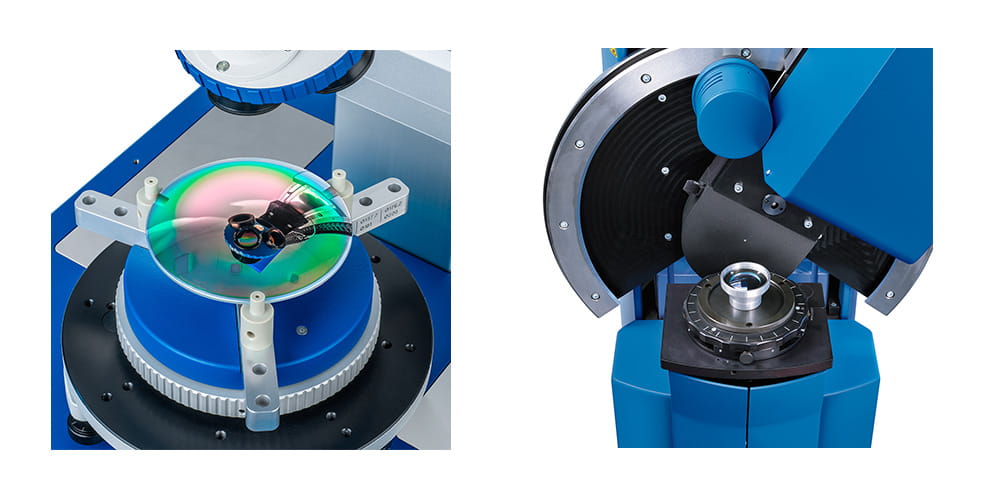

Quality control of imaging optics

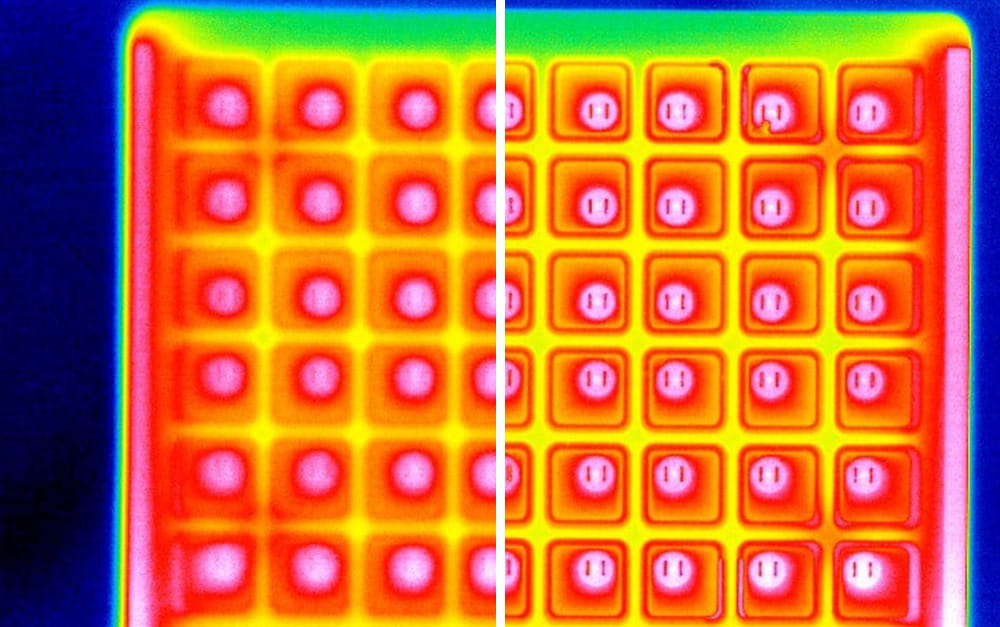

The dependence of the imaging quality on the lenses and their alignment requires objective quality control. The measuring systems must either operate in the visual spectral range and measure in reflection, or be matched to the wavelength of the sample → video. As with all optics, parameters such as center thickness, centering and MTF are important quality criteria. In addition, non-contact measurement is often required.Active alignment of camera modules

A good lens alone is not enough to achieve high image quality – the exact alignment of the lens to the camera sensor is also crucial for the image produced. Manual alignment of the optics to the sensor is uneconomical for large quantities. The requirement for low production tolerances also rules out manual alignment. Active alignment is therefore the most suitable manufacturing process for automated camera productionApplications

The different bands of the infrared spectrum are used for different applications:

SWIR and NIR

Spectroscopy: Detection of damage or different fillings for food sorting and quality control, wafer inspection or plastic type detection.

MWIR

High resolution, high contrast static images. Images are often output in black and white or false color without reference to temperature.

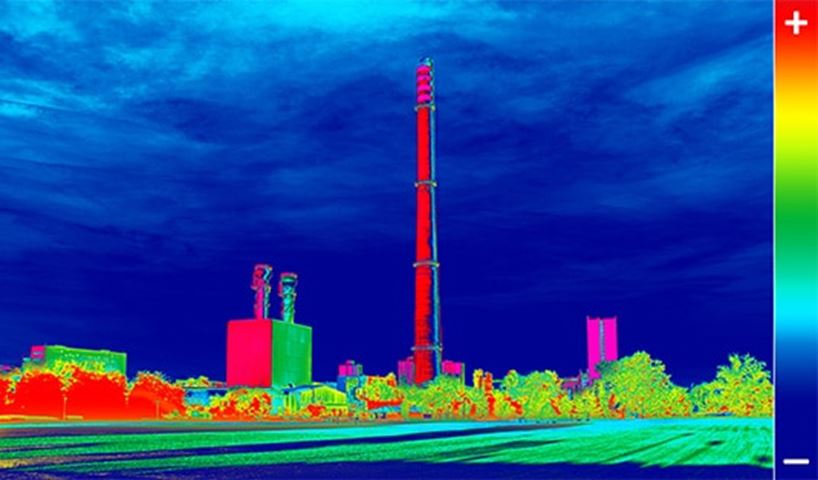

LWIR

Display of temperature information in calibrated instruments – classic thermal imaging camera.

Video-insight on IR optics:

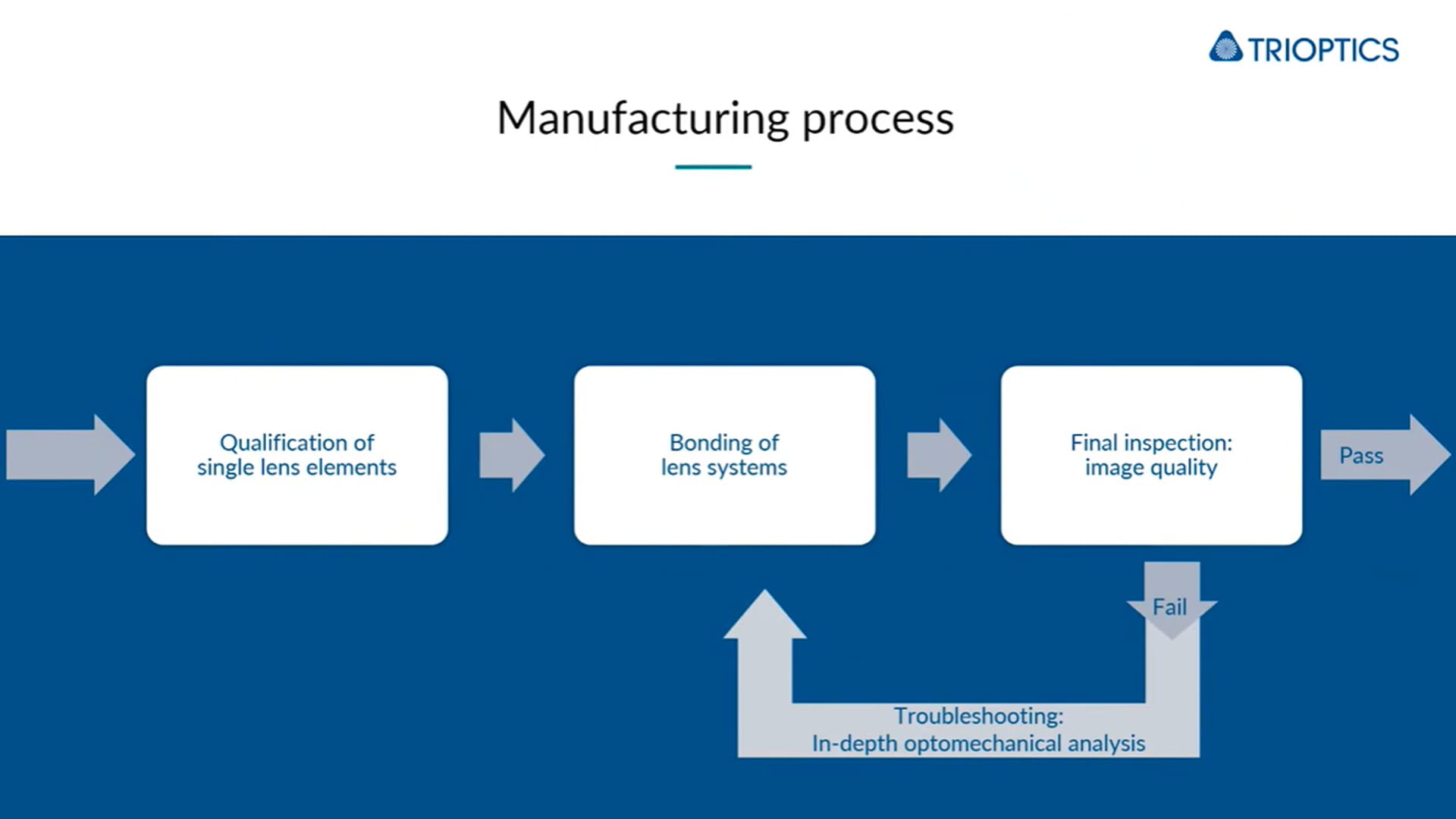

Efficient testing throughout the manufacturing process

In this contribution, we present solutions how to make the manufacturing process of IR objective lenses most efficient by using adequate techniques for centration-based alignment testing, IR MTF analysis and non-contact determination of center thicknesses and air spacings.

Boost your IR camera module

- Are you ready to take your camera module production to the next level?

- Do you want to streamline the alignment of lens and sensor?

- Do you want to boost your camera production speed and efficiency?

Discover the benefits of active alignment for your LWIR camera

- It optimizes the optical performance of your IR camera

- reduces manufacturing tolerances

- ensures a consistently high camera quality

Get ready to revolutionize your production process with active alignment!

Learn more about our active alignment equipment or get in touch with our experts to help you with your optical measurement and alignment task.

Discover our products

Our Newsletter – Your advantage in knowledge

Be one of the first to experience ourproduct novelties and innovative application possibilities.